Déconnecté1 888 344-4424EN

-

Champ d’application

- Tous les produits

- Santé - Sécurité

- Prothèses amovibles

- Tous les produits

- Prise d’empreintes et registres

- Coulée des modèles et MEA

- Reproduction de modèle et prothèse

- Cirage & montage

- Mise en moufle

- Acrylique - Bourrage - Injection

- Échaudage - Cuisson - Démouflage

- Meulage / coupage / sablage

- Adaptation

- Polissage - Finition

- Prothèses sur implants

- Réparations - renforts

- Rebasage & Conditionnement

- Autres matériaux

- Accessoires Bucaux

- Boîtes et emballage

- Meubles

- Prothèses fixes

- Tous les produits

- Coulée des empreintes

- Grossissement

- Fabrication des modèles et MEA

- Cirage, maquettes

- Procédé Céramique

- Tous les produits

- Stratification de céramique

- Lingotins

- Fours et accessoires de cuisson

- Couper - Former - Texturer

- Maquillage et glaçure

- Polissage

- Cimentation et Mordançage

- Procédé Métal

- Procédé Zircone

- Procédé composite

- Mise en revêtement

- Enfournement - Dépouillage

- Adaptation

- Boîtes et emballage

- Pièces squelettiques

- Orthodontie

- Tous les produits

- Fabrication de modèles, mise en articulation

- Reproduction de modèle

- Cirage

- Instruments et équipements

- Pinces pour fils métalliques

- Fils métalliques

- Acryliques Ortho & additifs

- Acryliques pour plaques occlusales

- Thermoplastiques

- Meulage / coupage / sablage

- Polissage - Finition

- Boîtes et emballage

-

Produits

- Tous les produits

- Produits DenPlus

- Acryliques

- Tous les produits

- Résine DenPlus

- Résines à cuisson conventionnelle

- Résine pour cuisson par micro-ondes

- Résine fluide pour coulée

- Résines de réparation

- Résines auto-polymérisables pour porte-empreintes

- Résines pour regarnissage

- Résines orthodontiques

- Résines thermoflexibles

- Résines radiopaques

- Résines teintes de dent

- Abrasifs, Fraises, Polissoirs et Disques

- Tous les produits

- Abrasifs

- Fraises

- Tous les produits

- Mini-catalogue fraises au carbure Diaswiss

- Fraises au carbure pour pièce à main

- Fraises spécialisées

- Fraises au carbure pour moteur

- Fraises pour turbine haute vitesse

- Fraises Infiniti pour pièce à main

- Fraises avec revêtement nitrure de titane

- Fraises DLC (Diamond-Like-Carbon)

- Fraises diamantées électroplaquées

- Fraises diamantées frittées

- Fraises pour finition des bases molles

- Pour technique de fraisage parallèle

- Fraises pour zircone

- Fraises Typhoon

- Organisation fraises

- Disques

- Roues et pointes abrasives, polissoirs

- Tous les produits

- Roues abrasives et pointes pour acryliques

- Roues abrasives et pointes pour zircone

- Roues et pointes d’oxyde d’aluminium

- Roues et pointes en carbure de silicium

- Roues pour meulage sans chaleur (Heatless)

- Meules pour moteur

- Bandes abrasives

- Roues et pointes en polyuréthane

- Roues et pointes en caoutchouc

- Roues et pointes en silicone

- Mandrins

- Roues pour taille-modèle

- Accessoires

- Articulateurs et arcs faciaux

- Brûleurs

- Numérique

- Tous les produits

- Mini-catalogue Numérique

- Logiciels

- Scanners dentaires

- Impression 3D

- Usinage

- Céramiques

- Cires

- Dents

- Die et modèle

- Boîtes et Emballage

- Empreintes

- Tous les produits

- Accessoires pour matériaux d’empreinte

- Polysulfure

- Adhésifs pour porte-empreintes

- Alginates

- Base de caoutchouc

- Bols de mélange

- Enregistrement occlusal

- Pistolet et embouts mélangeurs

- Polyéther

- Porte-empreintes

- Masques gingivaux

- Mastic pour empreintes

- Nettoyants pour alginate

- Seringues pour alginate

- Thermoplastiques - Composés

- Vinyl Polyether Silicone (VPES)

- Vinyl Polysiloxane (VPS)

- Oxyde de zinc - Eugénol & Non-Eugénol

- Équipements

- Tous les produits

- Anti-éclabousseurs

- Bains ultrasoniques

- Balances

- Burins électriques/pneumatiques

- Chauffe-cire

- Clinique

- Collecteurs de poussières

- Détoureuse pour arche

- Échaudeuses pour cire

- Coulée métaux

- Foreuse à goujons

- Fournaises

- Hottes et purificateurs d’air

- Lampes

- Loupes

- Mélangeurs

- Mélangeurs pour hydrocolloïde

- Meuleuses/polisseuse à haute vitesse pour métal

- Micromoteurs - pièces à main

- Microscopes

- Moteurs

- Moulage sous vide

- Nettoyeurs à vapeur

- Nettoyeurs de prothèses

- Équipement à photopolymériser

- Polissoirs

- Pots à pression

- Presse Hydraulique

- Systèmes à injection

- Sableuse

- Spatules chauffantes

- Stérilisateurs et autoclaves

- Taille-modèles

- Trappes et bennes à plâtre

- Turbines haute vitesse

- Unité de soudage

- Unités de cuisson pour prothèse

- Vibreurs

- Instruments

- Matériaux photopolymérisants

- Meubles

- Moulage sous vide

- Orthodontie

- Pinceaux, Brosses et polissoirs

- Plâtres, pierres et revêtements

- Ponts & couronnes

- Prévention et cosmétique

- Produits chimiques

- Prothèses amovibles

- Tous les produits

- Résines pour base dentaire

- Regarnissage de prothèse

- Prothèses partielles

- Accessoires pour prothèses

- Tous les produits

- Caractérisation

- Crochets métalliques

- Crochets en plastique

- Feuilles séparatrices - mise en moufle

- Fibres

- Fils

- Presse à rebasage

- Jauges, Compas, Plan occlusal

- Liquide séparateur

- Matériaux à duplication

- Moufles et brides

- Moufles pour duplication

- Pâte isolante

- Plaques bases

- Polissage

- Treillis et renforts

- Sécurité

- Usage unique

-

Équipements

- Tous les produits

- Anti-éclabousseurs

- Bains ultrasoniques

- Balances

- Burins électriques/pneumatiques

- Chauffe-cire

- Clinique

- Collecteurs de poussières

- Détoureuse pour arche

- Échaudeuses pour cire

- Coulée métaux

- Foreuse à goujons

- Fournaises

- Hottes et purificateurs d’air

- Lampes

- Loupes

- Mélangeurs

- Mélangeurs pour hydrocolloïde

- Meuleuses/polisseuse à haute vitesse pour métal

- Micromoteurs - pièces à main

- Microscopes

- Moteurs

- Moulage sous vide

- Nettoyeurs à vapeur

- Nettoyeurs de prothèses

- Équipement à photopolymériser

- Polissoirs

- Pots à pression

- Presse Hydraulique

- Systèmes à injection

- Sableuse

- Spatules chauffantes

- Stérilisateurs et autoclaves

- Taille-modèles

- Trappes et bennes à plâtre

- Turbines haute vitesse

- Unité de soudage

- Unités de cuisson pour prothèse

- Vibreurs

-

Numérique

- Tous les produits

- Mini-catalogue Numérique

- Logiciels

- Scanners dentaires

- Impression 3D

- Tous les produits

- Imprimantes Shining 3D

- Imprimantes Phrozen

- Imprimante Renfert

- Imprimantes Flashforge

- Résines 3D

- Nettoyage

- Post-polymérisation

- Adhésifs, séparateurs, Rebasage, glaçure

- Usinage

- Dents

-

Fabricants

- Tous les produits

- 3M ESPE

- American Tooth Industries

- ASA Dental

- Aurelia par Supermax Healthcare Canada

- Bausch

- Beaverstate Dental

- Besqual

- Brewer

- Buffalo Dental

- Canadian Hospital Specialities Ltd

- CMP Industries

- Crosstex

- Dedeco

- DenPlus

- Dental Creations

- Dentalfarm

- Dentsply

- Detax

- Diaswiss

- Dreve

- DTS

- Esma Incorporated

- exocad

- FAG Dentaire

- Flashforge

- Foredom Electric

- Garreco

- GC America

- Grobet

- Hager

- Hammacher

- Handler

- Hatho

- Invent Dental

- Isonic

- Kerr

- Keystone Industries

- Kube Innovation

- Lang Dental

- Lascod

- LeoneAmerica

- Maestro 3D

- Malzer Dental

- Mark3

- Meta Dental

- Micrylium

- MPF Brush Co

- Myerson

- Nabertherm

- NK-Optik

- Pac-Dent

- Phare Médica

- Phrozen

- Pi Dental

- Prodont Holliger

- pro3dure medical

- PRO-TECH

- Protechno

- Quatro Air

- Ransom & Randolph

- Ray Foster

- Razertip

- Reliable Corporation

- Renfert

- Saeyang

- Scantist 3D

- Schottlander

- Shenpaz

- Shining 3D

- Song Young

- Synca

- Tapmaster

- Tokuyama Dental

- Uvitron International

- Vacalon

- Vita

- Wells Dental

- Whip Mix

- Winder Research

- Yamahachi Dental

- Yates Motloid

- Yeti

THERMEO®

Disque thermoflexible usinable, clair, 98 x 16 mm

THERMEO® est flexible.

Qui ne le sait pas - "empreintes tordues" lors de la prise d’empreinte conventionnelle ou imperfections lors de la numérisation intra-orale qui conduisent à des "trous de données" à la surface de l’ensemble de données généré ? Une attelle dure conventionnelle vacille alors sur le modèle en plâtre et donc dans la bouche du patient. L’attelle est alors plus sollicitée, le risque de fracture est significativement augmenté et le patient se plaint d’un manque de confort de port. Le matériau unique de l’attelle THERMEO® compense ces imprécisions grâce à son effet thermomémoire breveté. Le matériau THERMEO® devient flexible à la température du corps et s’adapte de manière optimale à la surface de la dent. Cela augmente le confort de port de l’attelle et minimise le risque de rupture. THERMEO® soutient ainsi la satisfaction du prothésiste dentaire, du dentiste et du patient grâce à une plus grande sécurité, un confort de port exceptionnel et moins de « rappels ».

THERMEO® est intelligent.

Les matériaux intelligents/matériaux réactifs sont des matériaux qui réagissent indépendamment aux conditions environnementales changeantes telles que la température. Cette réaction est réversible. Les plastiques high-tech de la famille THERMEO® appartiennent à ce groupe de matériaux intelligents et se caractérisent par un effet thermomémoire breveté unique. Par rapport aux gouttières dentaires dures, les imprécisions lors de la prise d’empreinte peuvent ainsi être compensées avec une gouttière THERMEO®. Les produits THERMEO® permettent également de réaliser des gouttières thérapeutiques fonctionnelles. Les attelles THERMEO® se caractérisent par un confort de port élevé et sont auto-ajustables grâce à l’effet thermomémoire. Les propriétés spéciales de THERMEO® combinent les avantages des matériaux d’attelle durs et mous.

THERMEO® est confortable.

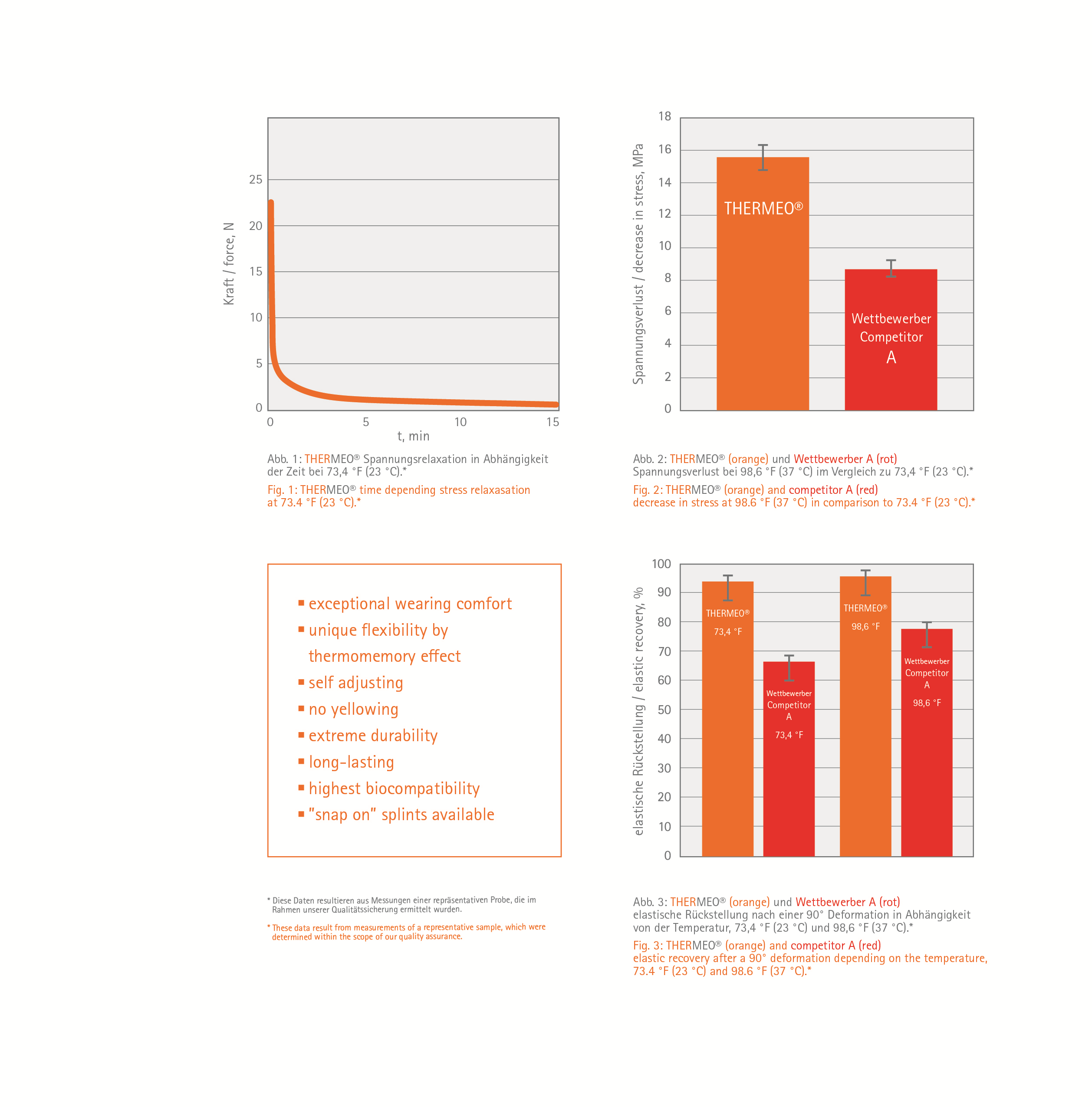

THERMEO® répond aux plus hauts standards de technologie médicale. Par exemple, THERMEO® n’utilise pas de plastifiants à base de phtalates, mais utilise à la place une technologie de flexibilisation brevetée qui assure une biocompatibilité unique dans cette classe de matériaux. Par rapport à d’autres fournisseurs, cela se traduit par une chute de pression nettement plus importante sur la dent après l’insertion de l’attelle (Fig. 1 et 2), ce qui augmente à son tour le confort de port pour le patient. De plus, du fait de la technologie utilisée, l’effet thermomémoire et donc la résilience du matériau THERMEO® est supérieur à celui des concurrents (Fig. 3). L’attelle THERMEO® revient à sa position d’origine plus rapidement et plus précisément grâce à la température corporelle. THERMEO® peut être traité de manière conventionnelle par la technique de coulée ou de bourrage-pressage ou intégré dans le flux de travail numérique sous forme de flans THERMEO®. Les ébauches sont disponibles en épaisseurs de 16 mm. Cela permet de fabriquer efficacement des attelles à appui dentaire et à appui sur tissus mous. Aussi bien le système poudre/liquide que les rondelles de fraisage sont également disponibles en tant que THERMEO® SO dans les teintes A1, A2 et A3 pour la fabrication de "snap-on splints".

Infolettre

Pour recevoir nos nouvelles et promotions

© 2026 DenPlus Inc. | Copyright | Conception Web : ViGlob